The Allied Farmers Project

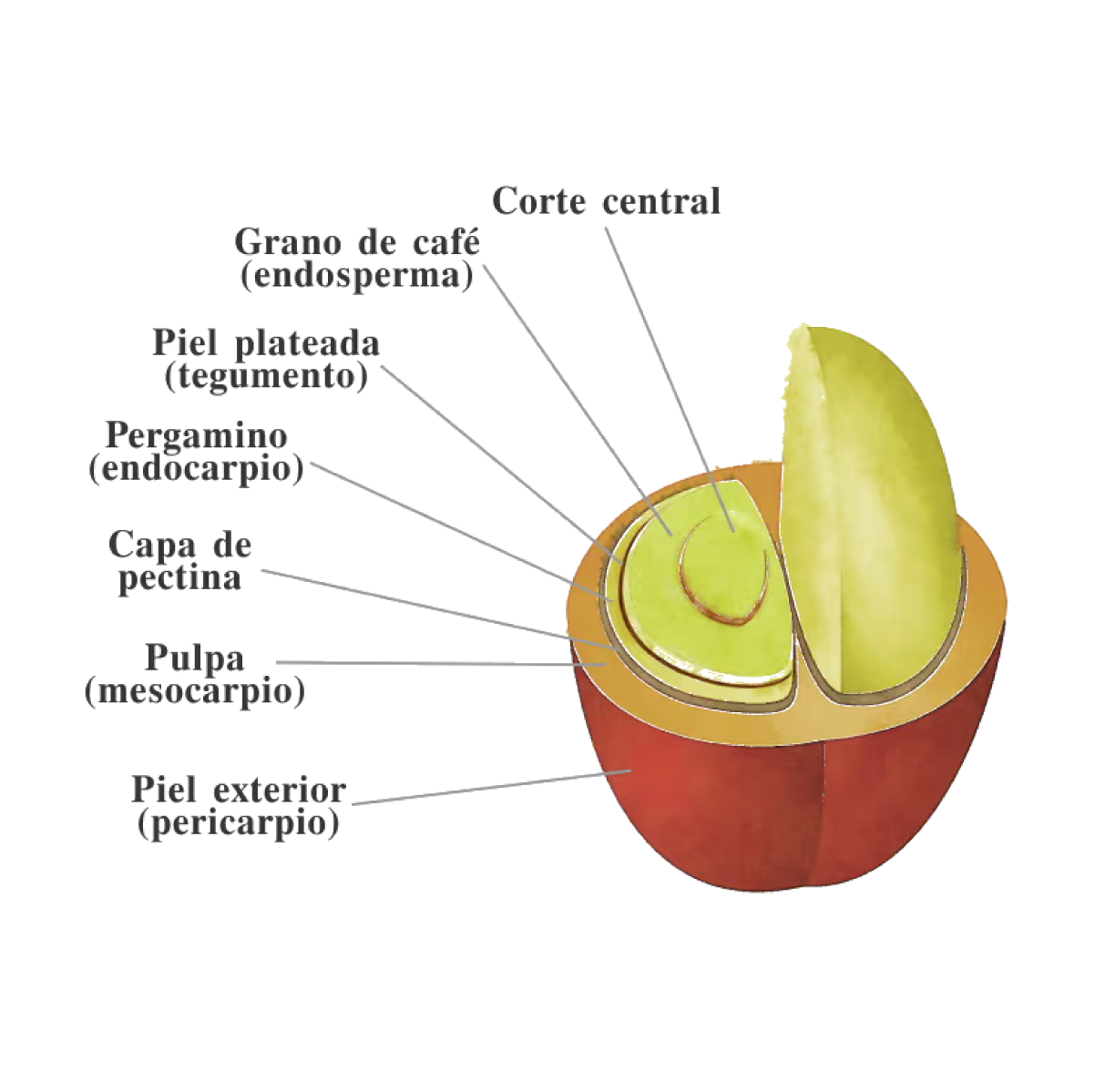

Remember that the coffee we consume is the roasted seed of a fruit. The fruit begins its process of transformation when it is picked from the tree. Unlike other fruits (such as banana, avocado, mango, etc.), coffee can’t be picked while it is still green. It must be harvested at the perfect point of ripeness, when the cherry has fully matured.

Once collected, the fruit must be processed on the farm. The main processing methods are:Washed, HoneyandNatural.

Washed

1. The coffee is mechanically de-pulped, removing the cherry.

2. Next, it is fermented in a tank for an average of 18-24 hours. This process helps detach the mucilage (the fleshy interior of the coffee fruit) from the bean, which is then washed thoroughly with water.

3. Small producers usually dry the beans in the sun — a slower and more careful approach to processing, which helps preserve quality. Beans can also be dried mechanically in silos.

Popularized by Colombian producers in the early 20th century, washed processing remains the most common methodology used among producers of high-quality coffees. The fermentation process, when done in a controlled manner, can greatly improve cup quality. During this process, natural yeasts and bacteria from the surrounding environment break down the mucilage, separating it from the grain and leaving behind several different by-products, including fatty acids like terpenes and esters. These fatty acids, which dilute in the water during coffee extraction, add great complexity to the final cup.

Tip: If done with care, combining beans harvested across multiple days, fermentation can go on for 5 days without damaging the coffee. Longer periods of fermentation can lead to very complex cups with high levels of sweetness. This process, however, has its risks.

A similar process is used by many larger farms, which, instead of fermenting the cherries, remove the mucilage mechanically, saving time and water. Leaving out the fermentation process, however, affects the sensory qualities of the end product.

HONEY (Semi-washed)

1. The coffee is mechanically de-pulped, removing the cherry.

2. Instead of being left to ferment in a tank, the coffee goes directly to drying. Fermentation is more aggressive when it occurs during the drying process — resulting in a final cup with notes of ripe fruit.

Natural

1. The coffee cherries are dried directly, without de-pulping or washing. Fermentation occurs during drying, but is even more intense than in honeys.

This process is used primarily among poor quality coffees, since they are not considered worth processing. However, if carefully done, Natural processing can result in very complex, sweet cups. This method of fermentation boosts the production of acetic acid, as well as some fatty acids that produce notes of ripe fruit or fruit wines.

METHODS OF DRYING

Sun drying

Most small coffee growers in Colombia and around the world dry their coffee in the sun. In countries like Colombia, farmers use structures with plastic roofs, called parabolic beds, to protect the beans from rain during the drying process. Farmers in drier regions, like Central America, typically dry their beans on concrete patios in open air.

Sun drying promotes quality, as the beans dry at lower temperatures and with pauses at night. This allows the bean to contract in a slow and controlled manner, losing around 50% of its size from wet to dry. If contraction occurs too rapidly, the cell walls of the bean can be broken and its aromatic components lost, affecting the quality of the end product.

Sylo drying

Mechanical silos are another popular method of drying coffee, used primarily by medium and large producers. Although there are several methods of silo drying, they all work based on the same principle: the silo is filled with hot air, drying out the beans’ moisture. Silos usually run between 45-60 degrees Celsius, and can dry coffee in less than 36 hours. Although they will never be quite as beneficial as natural heat from the sun, silos can successfully dry beans without damaging them, provided that a low temperature is maintained. However, most silos are operated at scorchingly high temperatures, damaging the structure of the beans, which contract and lose moisture too rapidly. Accelerated drying of this nature leads to a loss in aromatic components, and prematurely kills the embryo, causing the beans to age more quickly.

TRILLA OR DRY MILLING

This is the final process before roasting or exporting. The parchment is removed, and beans are separated by: SIZE, DENSITY and COLOR:

Pasilla:

Defective beans that have been broken, damaged by pests, or turned vinegary. These lower-quality beans are used for cheap coffees, sold domestically by large corporations.

Seguir Leyendo

-

01. Introduction

See moreWe are privileged to work in every stage of the coffee process — from farm to cup.

-

02. What are specialty coffees?

See moreWe’ll begin by defining specialty coffees — and what differentiates them from lower-quality beans.

-

03. Describing coffee

See moreCoffee is like wine. There’s the gas-station kind that taste like sludge, the critically-acclaimed kind that experts and hipsters alike hail as tasting like bouquets of flowers — and everything in between.

-

04. Agronomy

See moreThe process begins with a seed (the coffee bean itself) planted in sand, where it germinates into a small seedling called a “chapola.” After 3 months, the seedling is transplanted into a small bag, and continues to grow until it is strong enough to be planted in the field.

-

05. Farm processing

See moreRemember that the coffee we consume is the roasted seed of a fruit. The fruit begins its process of transformation when it is picked from the tree. Unlike other fruits (such as banana, avocado, mango, etc.), coffee can’t be picked while it is still green. It must be harvested at the perfect point of ripeness, when the cherry has fully matured.

-

06. Roasting

See moreAt Pergamino, we are artisanal roasters. is means several things. First, that we roast in small batches under the careful oversight of a master roaster. We analyze each batch of green coffee in depth in order to determine the ideal roasting curve for its density, profile and final destination.

-

07. Species of trees

See moreAt Pergamino, we are artisanal roasters. is means several things. First, that we roast in small batches under the careful oversight of a master roaster. We analyze each batch of green coffee in depth in order to determine the ideal roasting curve for its density, profile and final destination.

-

08. Extraction theory

See moreAs you can see, behind each cup of coffee is a world of complexity — meaning that we have a huge responsibility at the moment of the final brew. At Pergamino, we are very proud of our team of baristas, who assume this responsibility with great professionalism. They receive constant training, not only in the preparation of our drinks, but in the entire backstory of our coffees, and how to pass on their unique stories to our customers. But do not worry — with a little discipline and curiosity, you, too, can learn to make excellent coffee at home!

-

09. Preparation of filtered coffee

See moreBefore going into detail about brewing, we’d like to cover the core principles of coffee extraction. Brewing coffee is always a delicate game — balancing the quantity of coffee, the quantity of water, the type of grind, and the extraction time. Depending on the method, these factors can be varied in order to highlight specific attributes of a coffee.

-

10. History

See moreCoffee’s global voyage began in the lush highlands of Ethiopia, the original motherland of the Coffea Arabica plant. The earliest known writing on the coffee plant, dating to the 10th century, characterizes it as a medicine—prepared as an infusion of coffee cherries in hot water.

-

11. The Allied Farmers Project

See moreLike all small, medium and large producers in Colombia, Pergamino spent many years helplessly riding the roller coaster of international coffee prices. We had to invest in our crops without knowing what they would sell for during their 12-year production cycle.

-

12. Dreams of the future

See moreWe dare to share with you a dream that we have for the future. Colombian coffee has changed a lot in the last 80 years, shifting towards more technical, large-scale cultivation — with widespread use of chemical fertilizers, pesticides, monoculture, and complete exposure (without shade trees).

-

13. Brewing methods

See moreThese are our favorite methods and advices

-

Lomaverde (500g bag)

Santa Bárbara, Antioquia

Regular price $16.99Regular priceUnit price / per -

Decaf Lomaverde (500g bag)

Santa Bárbara, Antioquia

Regular price $18.99Regular priceUnit price / per -

Alto de Letras (500g bag)

Allied producers in Tolima

Regular price $18.99Regular priceUnit price / per -

Alto de letras x Potencia (500g bag)

Allied producers in Tolima

Regular price $20.99Regular priceUnit price / per